- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Availability: | |

|---|---|

| Quantity: | |

GZPK-83

SUPM

1

Pharmaceutical manufacturer's automatic high-speed tablet press

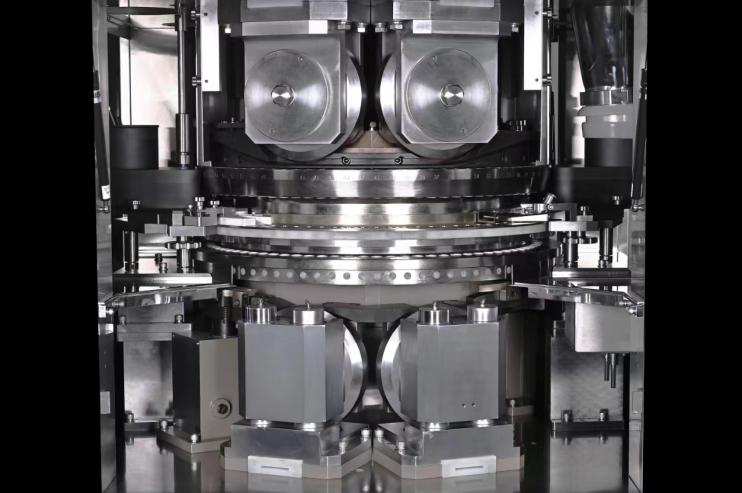

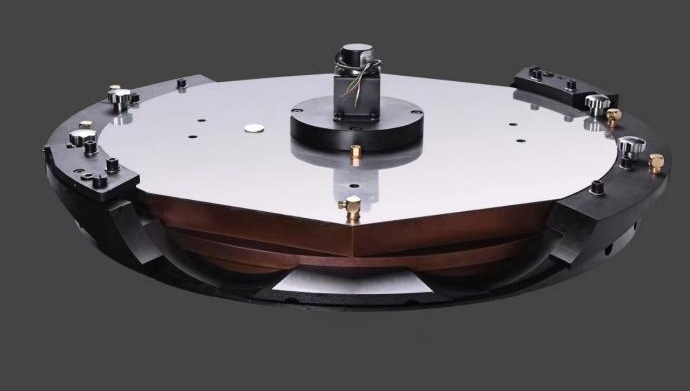

The part of the GZPK-83 tablet press machine is a fully enclosed tablet press chamber, the material metal in contact with the powder is acid-alkali resistant austenitic stainless steel, and the non-metallic material is non-toxic material. Four transparent Windows can be opened, so that the machine clean without obstruction, easy to replace the punch.

The lower part of the machine is sealed by four stainless steel doors with porous material inside, and contains various driving devices to ensure safety and reduce noise. The process of tablet pressing is completed by five steps: filling, measuring, pre-pressing, main pressing and tablet drawing. The operation of the tablet press is completely controlled by the touch screen on the electric control cabinet.

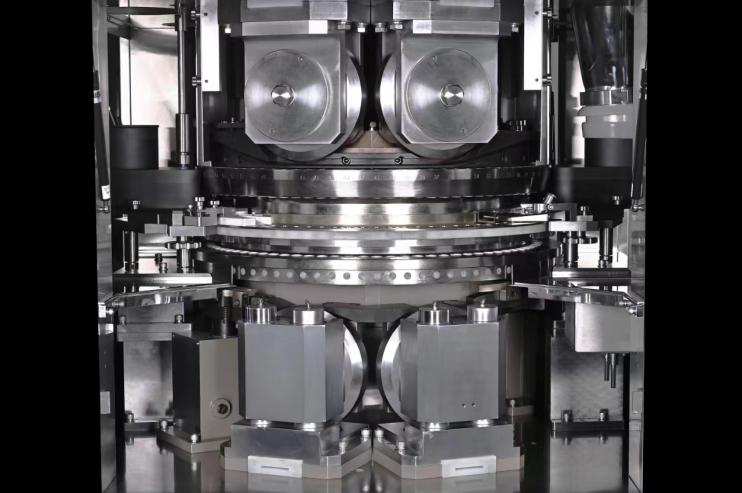

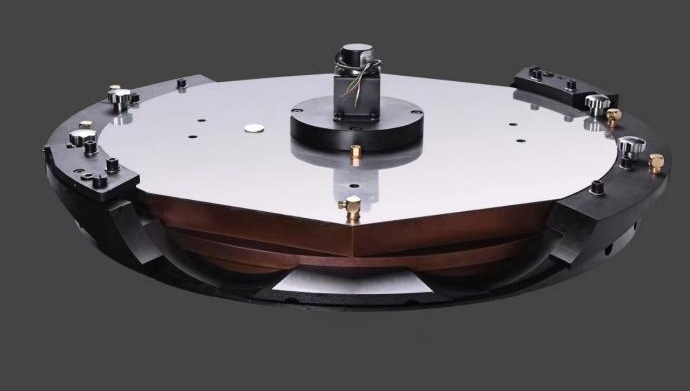

The main supporting structure of the GZPK-83 equipment is a four-column structure. As shown in the following figure, the bottom plate is equipped with a left and right stand, the left and right stand is equipped with a base plate, the base plate and the top plate are supported by four 140×140 columns, the height of the whole machine is only 1981, the center of gravity is low, so the equipment is very stable when running.

The upper main pressure wheel and the prepressure wheel are supported by two support plates, which are directly installed on the top plate, and finally the force is finally transmitted to the top plate and the column to ensure the pressure of the upper main pressure wheel and the prepressure wheel, and reduce the vibration and noise.

Model | GZPK-83 |

Number of punch | 83 |

R.P.M | 16~72 |

maximum output/h minimum output/h | 710000 160000 |

motor power(KW) | 11 |

maximum pressure(KN) | 100 |

13 | |

Maximum filling depth | 16 |

Maximum tablet thicknes(mm) | 8.5 |

pitch diameter(mm) | 720 |

Shank diameter of punch(mm) | 19 |

Middie height | 22.22 |

weight(Kg) | 5000 |

Pharmaceutical manufacturer's automatic high-speed tablet press

The part of the GZPK-83 tablet press machine is a fully enclosed tablet press chamber, the material metal in contact with the powder is acid-alkali resistant austenitic stainless steel, and the non-metallic material is non-toxic material. Four transparent Windows can be opened, so that the machine clean without obstruction, easy to replace the punch.

The lower part of the machine is sealed by four stainless steel doors with porous material inside, and contains various driving devices to ensure safety and reduce noise. The process of tablet pressing is completed by five steps: filling, measuring, pre-pressing, main pressing and tablet drawing. The operation of the tablet press is completely controlled by the touch screen on the electric control cabinet.

The main supporting structure of the GZPK-83 equipment is a four-column structure. As shown in the following figure, the bottom plate is equipped with a left and right stand, the left and right stand is equipped with a base plate, the base plate and the top plate are supported by four 140×140 columns, the height of the whole machine is only 1981, the center of gravity is low, so the equipment is very stable when running.

The upper main pressure wheel and the prepressure wheel are supported by two support plates, which are directly installed on the top plate, and finally the force is finally transmitted to the top plate and the column to ensure the pressure of the upper main pressure wheel and the prepressure wheel, and reduce the vibration and noise.

Model | GZPK-83 |

Number of punch | 83 |

R.P.M | 16~72 |

maximum output/h minimum output/h | 710000 160000 |

motor power(KW) | 11 |

maximum pressure(KN) | 100 |

13 | |

Maximum filling depth | 16 |

Maximum tablet thicknes(mm) | 8.5 |

pitch diameter(mm) | 720 |

Shank diameter of punch(mm) | 19 |

Middie height | 22.22 |

weight(Kg) | 5000 |