- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Availability: | |

|---|---|

| Quantity: | |

DXD-600 LI

SUPM

1

DXD-600 LI Sauce puree Automatic Packing Machine

Technical parameters of the entire unit:

model | DXD-600 LI |

Bag width | 100-250mm |

Bag length | 150-480mm |

Roll film width | 220-530mm |

packaging materials | Composite film (NY/PE, etc.) |

Packaging speed | 10-20 packs/minute (weight ≤ 1kg per pack) (depending on filling amount, material consistency, and environmental conditions) |

6-10 packs/minute (weight>1kg per pack) (depending on filling amount, material consistency, and environmental conditions) | |

Packaging capacity | Max.5000cc |

Sealing type | Back sealing and sealing |

power supply | AC 380V 50Hz |

Whole machine power | 7.5KW |

Gas source | 0.8-1.2 Mpa. (0.008m3/min.) |

External dimensions | L 1350mm * W 980mm * H 1980mm |

weight | 980kg |

4、 Performance characteristics

1). Local functions: fluid and semi fluid conveying, bag forming, weight adjustment, vacuum sealing, cutting, counting and other functions.

2. The appearance and molding parts of the whole machine are made of stainless steel, which is clean and hygienic, and meets food hygiene standards.

3. The computer operating system adopts imported color touch screen control, digital humanized management, and is equipped with various advanced functions such as automatic shutdown and timely alarm for shortage of materials and packaging materials, making operation simpler and maintenance more convenient.

4. The control part adopts Mitsubishi PLC programming control from Japan, which has stable and reliable performance, and is equipped with self checking prompt function.

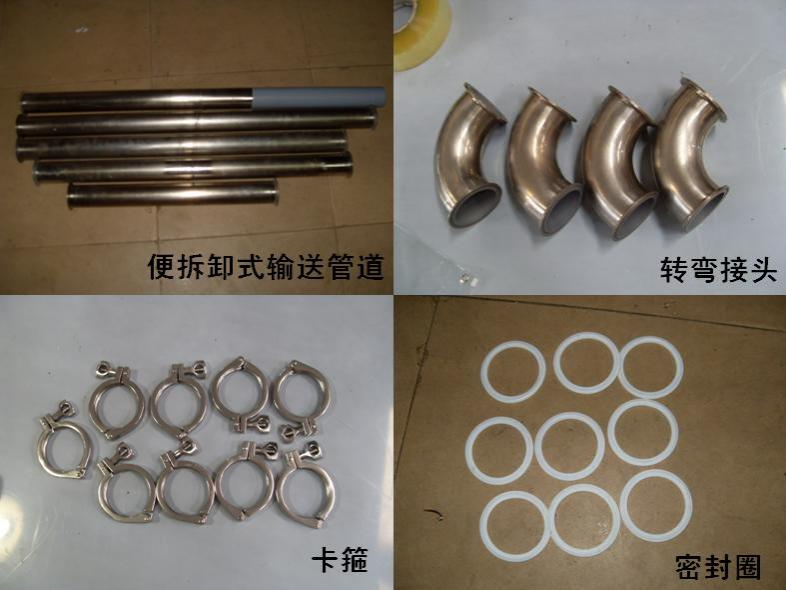

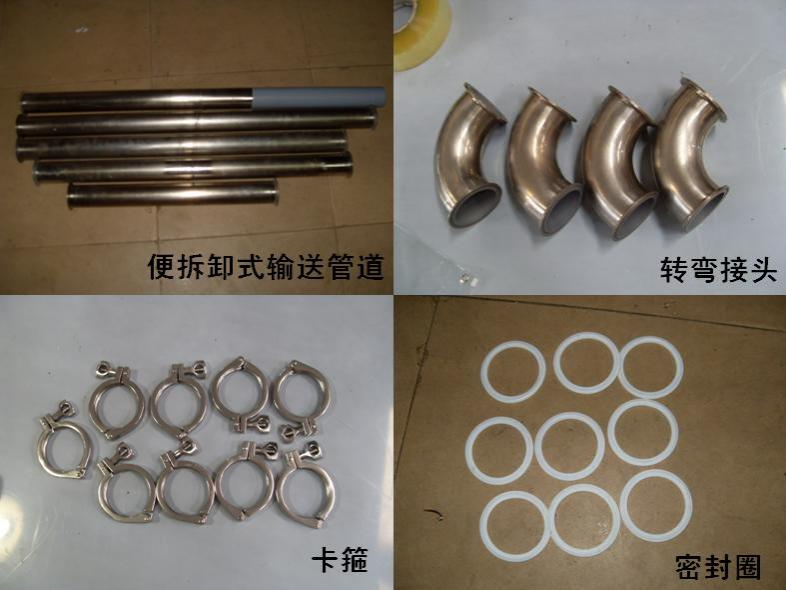

5. The conveying pipeline is made of stainless steel and can be treated with mirror or PTFE to ensure smooth and stable transportation of fillings and other viscous materials. The pipeline connection adopts quick installation joints, which are quick and easy to disassemble and clean.

6. Advanced control programs have been tested for a long time, resulting in a maximum packaging weight error of 0.6%, far below the national weight error standard.

7. The feeding pump is the first domestic brand, made of 304 stainless steel pump, which is sturdy, durable, stable, and has high standard pressure, especially suitable for conveying high viscosity materials.

8. The electrical components are made of international brand products, with reliable quality and easy self procurement and replacement.

9. The packaging capacity can reach over 1.8 tons per hour (5Kg/bag), and automatic filling and sealing can be completed above 85 ℃ to avoid secondary pollution, improve work efficiency, and reduce production costs.

10. Design a cleaning system specifically for pipeline characteristics, which is very convenient for cleaning pipelines.

11. Vacuum sealing not only improves product quality and extends shelf life, but also saves packaging film consumables and labor for customers, thereby saving operating costs.

12. Superior cost-effectiveness, high-quality performance, and reliable quality.

DXD-600 LI Sauce puree Automatic Packing Machine

Technical parameters of the entire unit:

model | DXD-600 LI |

Bag width | 100-250mm |

Bag length | 150-480mm |

Roll film width | 220-530mm |

packaging materials | Composite film (NY/PE, etc.) |

Packaging speed | 10-20 packs/minute (weight ≤ 1kg per pack) (depending on filling amount, material consistency, and environmental conditions) |

6-10 packs/minute (weight>1kg per pack) (depending on filling amount, material consistency, and environmental conditions) | |

Packaging capacity | Max.5000cc |

Sealing type | Back sealing and sealing |

power supply | AC 380V 50Hz |

Whole machine power | 7.5KW |

Gas source | 0.8-1.2 Mpa. (0.008m3/min.) |

External dimensions | L 1350mm * W 980mm * H 1980mm |

weight | 980kg |

4、 Performance characteristics

1). Local functions: fluid and semi fluid conveying, bag forming, weight adjustment, vacuum sealing, cutting, counting and other functions.

2. The appearance and molding parts of the whole machine are made of stainless steel, which is clean and hygienic, and meets food hygiene standards.

3. The computer operating system adopts imported color touch screen control, digital humanized management, and is equipped with various advanced functions such as automatic shutdown and timely alarm for shortage of materials and packaging materials, making operation simpler and maintenance more convenient.

4. The control part adopts Mitsubishi PLC programming control from Japan, which has stable and reliable performance, and is equipped with self checking prompt function.

5. The conveying pipeline is made of stainless steel and can be treated with mirror or PTFE to ensure smooth and stable transportation of fillings and other viscous materials. The pipeline connection adopts quick installation joints, which are quick and easy to disassemble and clean.

6. Advanced control programs have been tested for a long time, resulting in a maximum packaging weight error of 0.6%, far below the national weight error standard.

7. The feeding pump is the first domestic brand, made of 304 stainless steel pump, which is sturdy, durable, stable, and has high standard pressure, especially suitable for conveying high viscosity materials.

8. The electrical components are made of international brand products, with reliable quality and easy self procurement and replacement.

9. The packaging capacity can reach over 1.8 tons per hour (5Kg/bag), and automatic filling and sealing can be completed above 85 ℃ to avoid secondary pollution, improve work efficiency, and reduce production costs.

10. Design a cleaning system specifically for pipeline characteristics, which is very convenient for cleaning pipelines.

11. Vacuum sealing not only improves product quality and extends shelf life, but also saves packaging film consumables and labor for customers, thereby saving operating costs.

12. Superior cost-effectiveness, high-quality performance, and reliable quality.